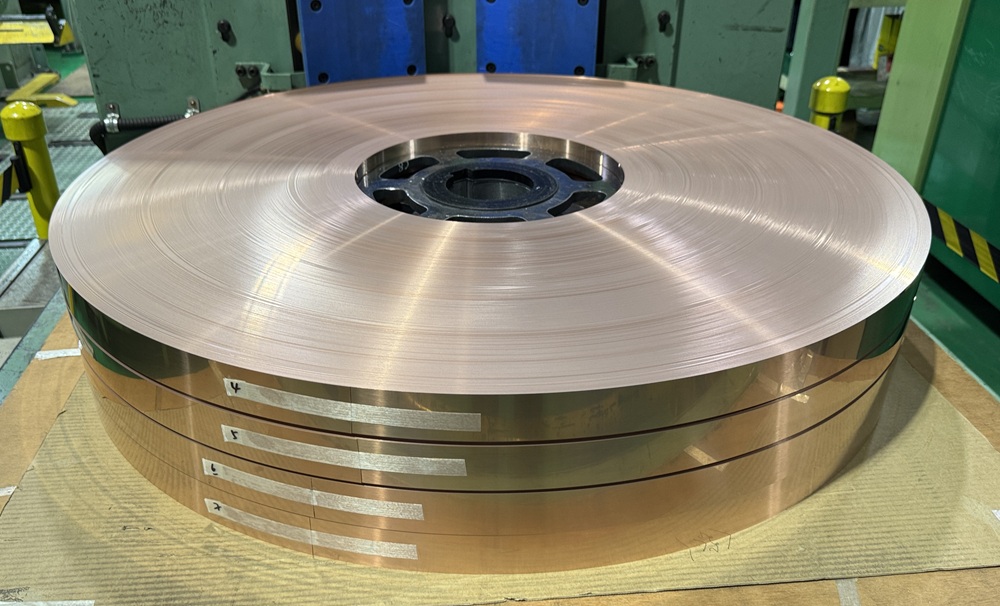

What is Copper alloys ?

Copper alloys are materials created by combining copper with other metals or elements to improve its physical, chemical, or mechanical properties. Copper itself is a versatile metal known for its excellent conductivity, corrosion resistance, and malleability. However, its pure form may lack the strength or durability needed for certain applications. Alloying copper with other elements helps to enhance its performance and expand its range of uses.

Why Create Copper Alloys?

Pure copper has limitations, such as:

- Low strength and hardness: It is too soft for applications requiring high wear resistance.

- Limited mechanical properties: It may deform under high stress.

To address these issues, alloying with metals like zinc, tin, nickel, or aluminum creates materials that are stronger, more durable, or have other desired qualities.

Key Properties of Copper Alloys

- Electrical and Thermal Conductivity

Most copper alloys maintain good conductivity, making them ideal for electrical and thermal applications. While not as high as pure copper, alloys like brass and bronze still perform well in such roles. - Corrosion Resistance

Copper and its alloys resist oxidation and corrosion, even in harsh environments. This makes them suitable for marine and industrial applications. - Versatility in Strength and Ductility

Copper alloys can be tailored for different combinations of strength and ductility, depending on the alloying elements and processing methods. - Aesthetic Appeal

Many copper alloys, such as brass, have an attractive appearance, making them popular for decorative applications.

Common Types of Copper Alloys

- Brass

- Composition: Copper + Zinc

- Properties: High malleability, resistance to corrosion, and a golden appearance.

- Applications: Musical instruments, plumbing fixtures, and decorative items.

- Bronze

- Composition: Copper + Tin (may include other elements like aluminum or phosphorus).

- Properties: Strong, wear-resistant, and resistant to seawater corrosion.

- Applications: Bearings, statues, marine equipment, and gears.

- Copper-Nickel Alloys (Cupronickel)

- Composition: Copper + Nickel

- Properties: Exceptional resistance to corrosion in seawater, high strength, and thermal stability.

- Applications: Shipbuilding, heat exchangers, and coinage.

- Aluminum Bronze

- Composition: Copper + Aluminum

- Properties: High strength, excellent wear and corrosion resistance.

- Applications: Aerospace, marine hardware, and industrial equipment.

- > Titanium Copper

- > Corson Alloys

- > Phosphor Bronze

Applications of Copper Alloys

- Electrical and Electronics: Wiring, connectors, and components where conductivity is crucial.

- Construction and Plumbing: Pipes, roofing materials, and fittings due to their durability and resistance to corrosion.

- Marine Industry: Propellers, ship hulls, and desalination equipment, thanks to their resistance to seawater corrosion.

- Art and Sculpture: Decorative items and statues because of their aesthetic qualities and ease of casting.

- Machinery: Bearings, bushings, and gears that require wear resistance and low friction.

Advantages of Copper Alloys

- Ability to customize properties for specific applications.

- Long lifespan due to durability and corrosion resistance.

- Recyclability, making them an environmentally friendly choice.

Copper alloys are fundamental materials in many industries, combining copper's natural properties with enhanced features provided by alloying elements. These versatile materials are essential for modern technology, infrastructure, and art.

If you would like to know more about Copper Alloys, please contact us.

Please feel free to contact us607 557 76608:00-17:00(Weekdays)

Contact We are looking forward to hearing from you!